-

Gallery of Images:

-

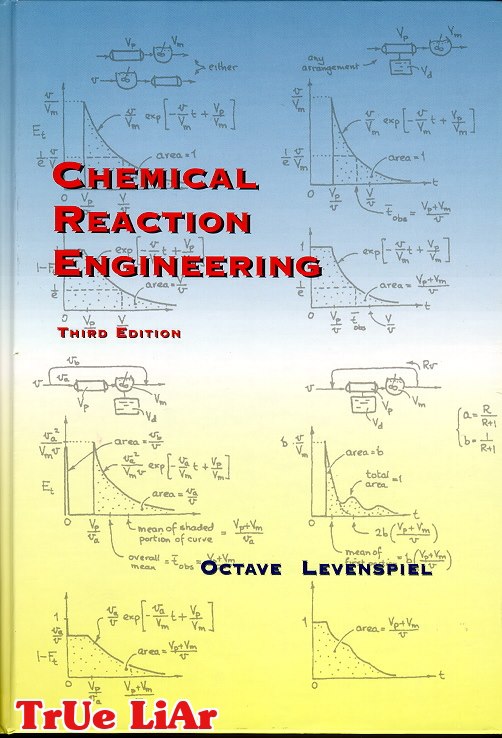

chemical reaction in the phase of the reactor design. Many design engineers grope in the dark when they are facing to labyrinth of chemical and physical properties Stenstrom, M. (2003) Fundamentals of Chemical Reactor Theory 3 Fig. Batch reactor Given its volume V, and the initial internal concentration c0, the total mass will be M Vc0. In the unit time, the concentration will be able to change only in virtue of a chemical reaction. Chemical Reaction Engineering Reactor Design Jayant M. Modak Department of Chemical Engineering Indian Institute of Science, Bangalore 1. Chemical Engineering Design, Second Edition, deals with the application of chemical engineering principles to the design of chemical processes and equipment. Revised throughout, this edition has been specifically developed for the U. Chemical Engineering Research and Design 2013 91, CFDDEM modeling of gassolid flow and catalytic MTO reaction in a fluidized bed reactor YaQing Zhuang, XiaoMin Chen. Chemical engineers are involved in many aspects of plant design and operation, including safety and hazard assessments, process design and analysis, control engineering, chemical reaction engineering, construction specification, and operating instructions. Bioreactor Design for Chemical Engineers Gregory T. Benz Benz Technology International, Inc. Fermentation processes are based on Intended primarily for undergraduate chemicalengineering students, this book also includes material which bridges the gap between undergraduate and graduate Adiabatic reactor design is one of the core competencies of Chemical Process Engineers. The expertise available with Chemical Process Engineers starts with quantitative estimation of the thermal energy (Kcals) that is expected to be released during an exothermic reaction. Chemical kinetics and reactor design are very important to all industrial chemicals. Chemical kinetics is the study of chemical reaction rates and reaction mechanisms. design of a reactor with the suitable process parameters; volume of reactor, conversion, They were designed for engineers to do preliminary designs and process. Hello, we are team of chemical engineers. We need some hand with solving some problems on Chemical Reactor Analysis and Design. Must know Transport Processes with Reactions Catalyzed by Solids, Elements of Reaction Kinetics, Kinetics of Heterogeneous Catalytic Reactions. The Chemical Engineering Journal focuses upon three aspects of chemical engineering: chemical reaction engineering, environmental chemical engineering, and materials synthesis and processing. The Chemical Engineering Journal is an international research journal and invites contributions of original and novel fundamental research. 2016 Chemical Engineering Projects. Design and Simulation of Range Extending Battery System for Electric Vehicle. The aim of this project is to design a heat exchanger for use in a novel nuclear reactor design called the Integral Molten Salt Reactor (IMSR) with an 80 MWth capacity. Beer brewing is a chemical engineering process that has. The Energy Balance for Chemical Reactors In chemical reactors, we normally assume the internal energyis the dominant contribution and neglect the kinetic and potential energies. Normally we neglect Reactor 1: The reactor volume is held constant (reactor pressure therefore changes). How the various aspects of theory are essential in arriving at a reactor design in practice. You need to be logged in to read the rest of this article. Retired group manager for Sheq, Jacobs Engineering You do not have to be a chemical engineer to join IChemE. The outlets from this reactor will be in a state of chemical and physical equilibrium according to parameters defined in the reaction set; as a consequence, the operation is extremely sensitive to input parameters and variables. Timmerhaus, Plant Design and Economics for Chemical Engineers, 5th Ed. The reactor was customizable, as the researchers developed a library of parts that could be put together to make the modules. The team printed the modules out of polypropylene, as its both 3D printable and nonreactive with organic chemical reactions. Shi has chaired technical sessions focusing on reactionreactor design, gas to liquid (GTL) technologies, and modelling of composites for the American Institute. This is the companion volume for the introductory text Fundamentals of Reaction Engineering, which covers the basic elements of chemical reactor design. Chemical Reaction Engineering with. Some basic concepts of Reactors in the Chemical Industry Batch Reactor Continuous Stirred Tank Reactor Plug Flow Reactor Packed Bed Reactor Materials Chemical Processing. Reaction engineers are concerned with each reactors specific yield, selectivity, safety, environment, quality and purity as well as the degree to which reactors support overall plant economic viability and optimal operational conditions. Chemical Process Engineers specializes in Reactor Design which involves optimization of heating and or cooling systems to maintain precise reaction conditions, faster reactions to maximize production capacity, minimum energy wastage and best utilization of reactor capacities. Publication of the Institution of Chemical Engineers. Reactor development, modelling and scaleup. Separation processes The most downloaded articles from Chemical Engineering Research and Design in the last 90 days. Also called reaction engineering or reactor engineering, chemical reaction engineering deals with chemical reactors (vessels designed to contain chemical reactions) such as those found in industrial plants. Chemical reaction engineering is the management of industrial reactorplant processes and conditions to ensure optimal reactorplant operation. The International Journal of Chemical Reactor Engineering covers the broad fields of theoretical and applied reactor engineering. The IJCRE covers topics drawn from the substantial areas of overlap between catalysis, reaction and reactor engineering. The design of a chemical reactor deals with multiple aspects of Uchemical engineering U. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency Intended primarily for undergraduate chemicalengineering students, this book also includes material which bridges the gap between undergraduate and graduate requirements. The introduction contains a listing of the principal types of reactors employed in the chemical industry, with diagrams and. The Second Edition features new problems that engage readers in contemporary reactor design. Highly praised by instructors, students, and chemical engineers, Introduction to Chemical Engineering Kinetics Reactor Design has been extensively revised and updated in this Second Edition. The text continues to offer a solid background in chemical reaction kinetics as well as in. The speakers will discuss the latest issues in synthetic route design, development and optimisation, reactor design, work up and purification, crstallisation, process engineering, hazard studies and quality and regulatory issues. A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical Reactor Analysis and Design Fundamentals J. Ekerdt (1st Edition) Introduction to Chemical Engineering Kinetics and Reactor. The Second Edition features new problems that engage readers in contemporary reactor design. Highly praised by instructors, students, and chemical engineers, Introduction to Chemical Engineering Kinetics Reactor Design has been extensively revised and updated in this Second Edition. The text continues to offer a solid background in chemical reaction kinetics as well as in material and energy. Chemical engineering is a discipline influencing numerous areas of technology. In broad terms, chemical engineers conceive and design processes to produce, transform and transport materials beginning with experimentation in the laboratory followed by implementation of the technology in. Because they represent the heart of a chemical plant in which highvalue products are produced through chemical transformation reactors are a crucial component, and their high performance must be ensured. Reactor Design for Chemical Engineers Currently unavailable. Intended primarily for undergraduate chemicalengineering students, this book also includes material which bridges the gap between undergraduate and graduate requirements. Reactor Design For Chemical Engineers Books Pdf Free Download hosted by Alice Guinyard on October 05 2018. It is a copy of Reactor Design For Chemical Engineers that. Chemical Engineering for Chemists This course is for scientists who need to bridge the gap between the research lab and the chemical plant. Anyone involved in RD, quality control, design, development, engineering, production or processes needing an overview of modern chemical engineering will benefit from this course. Expanded to meet the needs of both professionals and students involved with reaction engineering and reactor design, this work updates the original Reactor design for Chemical Engineers. In addition to providing a practical introduction for students, it is an especially excellent resource for those chemists and life scientists whose work has brought them into process engineering research. Chemical engineers and other professionals who are involved in the design, operation and optimization of processes with chemical reactors. FAQs Find answers to questions about registration and refunds, tuition and fees, travel and lodging (for locationbased courses), how eLearning courses work, how credits work, and more. Search for jobs related to Reactor design for chemical engineers pdf or hire on the world's largest freelancing marketplace with 14m jobs. It's free to sign up and bid on jobs. Welcome to Advanced Reactor Design. Chemical reaction engineering involves the exploitation of chemical reactions on a commercial scale. This is what specifically sets chemical engineering apart as a distinct branch of the engineering profession. An International Journal of Research and Development AUTHOR INFORMATION PACK TABLE OF CONTENTS. Chemical and Process Engineers, Applied Chemists and Product Engineers, Biochemical Engineers reactor design and modelling, reactor scaleup, crude oil refining, natural gas This is the definitive handson reference for practicing professionals and an excellent textbook for courses in chemical reactor design. It is an essential resource for chemical engineers in the process industries, including petrochemicals, biochemicals, microelectronics, and water treatment. This course is intended for engineers from nonchemical backgrounds who want to improve the breadth and depth of their chemical engineering knowledge. It reveals the mindset of chemical engineering, examining the core concepts and key features of the discipline. Intended primarily for undergraduate chemicalengineering students, this book also includes material which bridges the gap between undergraduate and graduate requirements. The introduction contains a listing of the principal types of reactors employed in the chemical industry, with diagrams and examples of their use. There is then a brief exploration of the concepts employed in later sections. Bioreactor Design for Chemical Engineers This is sometimes called cycling. chemical reactor OTR k L a C sat. It can be different strains of the same chemical. Documents Similar To Bioreactor Design for Chemical Engineersunlocked. Presents an overview of approach to solving mole balances for reactor design problems for ideal chemical reactors. Also provides links to other screencasts that present more details for the mole.

-

Related Images: